The decarbonisation of the energy system is key for achieving long-term sustainability of the European society. Major actions should be taken to ensure secure, sustainable, affordable and competitive energy for households and industry. Achieving this goal will require a fundamental transformation of Europe’s energy system.

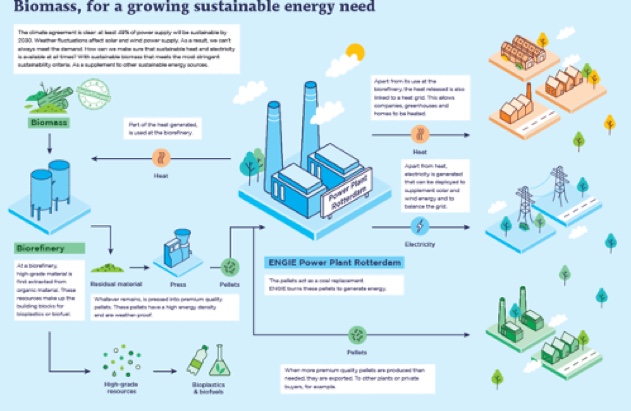

The Arbaheat project aims to develop and demonstrate a new concept for retrofitting of existing coal fired power plants via integration of a biomass thermal treatment technology. In the demonstration plant, steam is used to convert organic residual material to black pellets and high-grade bioliquids. The pellets have a high energy density and act as a coal replacement to generate energy in a coal fired power plant. The bioliquids can be processed in a biorefinery for usage by the chemical industry. The system of producing biocoals from biomass to replace fossil coals is an elegant solution as green chemicals can also be recovered from the biomass, thereby providing a promising alternative for a greener future.

The challenge

One of the key elements in the project is to design and construct an integrated demonstration plant. In the project eight different partners collaborate, next to the research program, on the delivery of a demonstration plant as an integrated solution at the Onyx (previously Engie) power plant.

These partners are diverse, ranging from the small scale-up company Arbaflame to the large powerplant owner Onyx (previously Engie) and research partners ECN TNO, UIB, Sintef, VUB and Port of Rotterdam. The partners all have different responsibilities in the project, but also different ways of working. Especially for the delivery of the demonstration plant, it turned out to be a challenge to match the different ways of approaching such a project.

While large corporates typically have standard specifications with hundreds of pages, a scale-up will typically specify in a functional way, leaving more responsibility with a vendor how to deliver the required quality. Bridging the gap between different company standards to deliver a design that is acceptable by all parties is a major challenge in this project.

The solution

TransitionHERO was requested to support PNO Consultants which is responsible for the consortium project management. As such TransitionHERO has become the technical lead for work package 4 of the project, which is the design and construction of the Arbaheat demonstration plant. In this role we are responsible to coordinate between the different participants and facilitate alignment regarding technical specifications. We look at the different technical requirements and propose solutions that are acceptable by all parties. For example, we have coordinated the Basis of Design, supported discussions regarding permitting needs such as additional filters, NOx reducing measures and solutions to make the integration more cost-effective by utilising existing assets.

In this role we support the partners in finding the balance between over-specifying and under-specifying, such that the design is safe, operable, maintainable and permittable.

Results

We have provided focus on developing a design that is safe, operable, maintainable and permittable. The team is now focused on the end result and is working together based on their common grounds. The result of the project so far is improved cooperation and alignment between partners regarding the wants and needs for the project.

The duration of the Arbaheat project is four years. Eventually the project is projected to demonstrate cost-effective transformation of a coal-fired power plant into a power plant running on green coal.

Get in touch

Do you want to challenge us with your case? Do not hesitate to contact us immediately.

Stef Clevers – energy specialist stef.clevers@transitionhero.nl

Adam Fontaine – parametric business case engineer – adam.fontaine@transitionhero.nl